SpotSee,

the global leader in shock, vibration and temperature monitoring through

low-cost connectivity and data, provides automotive suppliers and

manufacturers with real-time impact, tilt, vibration and location alerts

to identify issues within the supply chain through its monitoring

devices, SpotBot Cellular™.

This press release features multimedia. View the full release here:

https://www.businesswire.com/news/home/20190529005074/en/

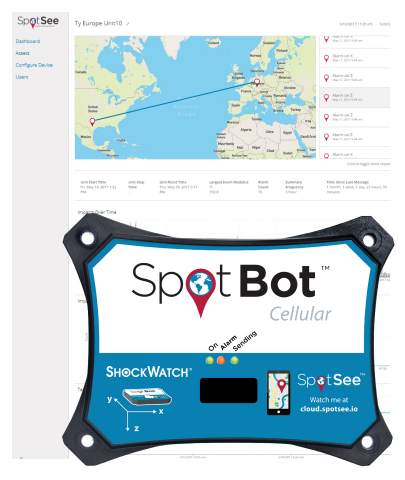

SpotBot Cellular (Photo: Business Wire)

SpotBot Cellular, a damage-monitoring device, can be placed on

automotive parts to track impacts sustained during transit. Auto parts

often travel through various warehouses before reaching the final

assembly line, providing several opportunities for damages to be

incurred. SpotBot Cellular can also be used to record changes in

temperature, and tilt and roll conditions. To avoid damage, items like

auto glass should remain in an upright position. As such, a SpotBot

monitor is attached to ensure minimal movement throughout transportation.

“Real-time alerts provide supply chain transparency and allow companies

to make necessary changes to ensure safer handling and transportation of

auto parts and components,” said Angela Kerr, vice president of product

portfolio, SpotSee. “Results vary based on situation, but the damage

rate typically drops by 50 percent or more when a monitor is in place.”

Identifying problems as they happen also increases the response to just

in sequence (JIS) supply and assembly line issues. A JIS strategy is

used to create a more efficient assembly line by delivering parts

according to a strict production timeline. If a piece of operating

equipment in a JIS assembly line is damaged, the schedule is delayed,

creating large windows of downtime. With real-time monitors in place to

alert operators of issues, companies can proactively maintain assembly

lines and repair equipment before complete failure occurs. This reduces

downtime and any associated costs.

Data collected from monitoring devices is stored in the SpotSee Cloud,

which can be accessed from any web-based device. This allows users to

access, visualize and analyze their data in real time from anywhere.

For more information about SpotBot or ShockLog, visit https://spotsee.io/impact.

About SpotSee

SpotSee is an internet of things end-to-end solution provider that

enables customers to spot damage in their operations and see it in real

time. SpotSee has developed a low-cost, connected ecosystem that

includes its own mobile virtual network enabler (MVNE) that delivers

data from devices anywhere in the world to customers’ fingertips.

SpotSee devices monitor shock, vibration, temperature and other

environmental conditions through its market-leading brands such as

ShockWatch®, ShockLog®, SpotBot™, OpsWatch and WarmMark®. The company

has a global network of over 300 sales and technical service partners in

62 countries. SpotSee is headquartered in Dallas, Texas, with operations

in Brazil, Netherlands, United Kingdom, China, Mexico and Graham, Texas.

For more information, visit www.spotsee.io.

View source version on businesswire.com: https://www.businesswire.com/news/home/20190529005074/en/